Liquid detergent packets were introduced to the North American market in 2010 and have since become an important product. They have grown in popularity because they provide a convenient way to deliver the correct dose of detergent for maximum cleaning efficiency. With increased use come more questions on what makes up the packets, especially the technology that goes into the PVA water-soluble film that encapsulates them. This page hopes to answer many of the common questions about PVA/PVOH films used in detergent packets.

Frequently Asked Questions

Q: What are laundry packet films made of?

A: Throughout the cleaning product industry, detergent pods and liquid detergent packets are made from water soluble films. These films are made of polyvinyl alcohol (known as PVA or PVOH). A great amount of research has gone into these films to ensure they are safe to use in the home, along with the ingredients they encapsulate, and that they fully dissolve and fully biodegrade in the environment after use.

Q: What Is PVA/PVOH (Polyvinyl Alcohol) and is it safe to use?

A: PVA stands for Polyvinyl Alcohol also known as PVOH (since the OH is the alcohol group when expressed in a chemical formula). It can be manufactured in a variety of ways and with a variety of purposes and properties. Uses range from more durable purposes such as fishing lines, papermaking, and textiles to pharmaceuticals including “artificial tears” and contact lens lubricants..

PVOH used in detergent products such as Liquid Laundry Packets (LLPs) and dishwasher packets are specifically designed to hold in concentrated laundry detergent liquid and be flexible and water resistant when packaged. However, the film then becomes soluble and biodegradable when used in washing. This enables the product to be made into single-dose packets that are convenient and reduce product packaging. It is due to these unique properties that EPA has named it a “Safer Choice” product, indicating that this innovative ingredient is safer for families and the environment.

Q: How is PVOH made?

A: PVOH used in detergent products is formulated using Ethylene Gas and Acetic Acid as the primary ingredients. The product is Vinyl Acetate that when processed further creates the films used to make detergent pods.

PVOH is typically made from fossil fuels/petroleum. The building blocks of the PVOH used in detergent film are oxygen (natural component of air), the gas ethylene (which is typically derived from petroleum or natural gas), and acetic acid (which is also typically made from petroleum or natural gas).

The ethylene used to create PVOH can be made from ethanol which can be sourced from corn, sugar cane, or sugar beet (bio-ethanol). The acetic acid used to create detergent films can also be made from bio-ethanol. Although PVOH films currently used in detergents are typically made from fossil fuels/petroleum, this will change as bio-based feedstocks become more available and cost-competitive.

Q: What are the benefits of PVOH films?

A: When used to contain detergents, PVOH films have several benefits:

- By encapsulating a single dose of a product, PVOH films are helping to take the guess work out of measuring. This is especially important for users with physical disabilities. It also prevents users from wasting detergent by using too much.

- The use of these films to make detergent packets also allows for use of more concentrated formulas. This means significantly less water in cleaning product formulas which means reduced packaging waste, less weight and fewer CO2 emissions from transporting these products.

- Encapsulating the highly concentrated detergent helps to make sure that users are not coming into contact with the products inside the detergent packet which could irritate skin.

Q: How is PVA film different from microplastics?

A: Microplastics are tiny, water-insoluble synthetic polymer particles. In California, they're defined as solid polymeric materials with dimensions between 1 and 5,000 µm. They can result from deliberate additions (like microbeads) or the breakdown of larger plastics. Microplastics can enter the food chain and are challenging to remove from the environment, posing a significant ecological concern.

Although PVA films have similar properties to many plastics such as flexibility, they fully dissolve in water when used and the dissolved polymers are fully biodegraded by microorganisms in water treatment facilities and the environment. Whereas microplastics are persistent in the environment and do not biodegrade.

Q: Are PVOH films biodegradable? How do they work?

A: Yes, PVA films are biodegradable and are eco friendly. When exposed to moisture and microorganisms, PVA breaks down into non-toxic components, making it a more sustainable alternative to traditional plastics.

(Reference - https://www.greenecodream.com/blogs/blog/what-is-pva-polyvinyl-alcohol-is-it-eco-friendly)

Q. What happens to detergent packet film once it leaves your hands?

A. Here's what a recent study found about what happens to that film once you use a detergent packet:

Scientific Papers

- ACI’s White Paper

This paper explores the water solubility and safety features of Polyvinyl Alcohol (PVOH) based films in liquid detergent capsules. It aggregates several studies, showing that the films used in laundry detergent packs fully biodegrade within 90 days, meeting international standards and posing no concerns for environmental persistence. - Application of Standardized Methods to Evaluate the Environmental Safety of Polyvinyl Alcohol Disposed of Down the Drain

The purpose of this research was to use polyvinyl alcohol (PVOH) 18‐88 as a case study to evaluate the environmental fate, ecotoxicity, and overall safety profile of water‐soluble, nonmodified PVOH polymers used in detergent films. An OECD 303A Wastewater Treatment Plant Simulation Study was conducted with dissolved organic carbon as the analytical endpoint to evaluate the removal of PVOH 18‐88 during wastewater treatment. - Biodegradability of Polyvinyl Alcohol Based Film Used for Liquid Detergent Capsules

This study looked at six types of PVOH films used in detergents and found that they all meet strict criteria for biodegradability, noting that PVOH has a similar structure to natural substances like cellulose. The study concludes that PVOH used in detergent capsules is not considered a microplastic because it is not tiny, dissolves easily in water, and biodegrades in the environment.

- Raw Material Supplier and Detergent Manufacturer Cooperate in Environmental Safety Assessment of a New Detergent Raw Material A Case Study

This case study reviews the data found from an extensive study on the environmental impact of a new material based on polyvinyl alcohol. The resulting data provided scientific evidence that it has a positive environmental profile. Biodegradation tests indicated significant removal of the material in sewage treatment and further tests classified it as non-persistent and posing no expected adverse effects on aquatic organisms.

- Some Characteristics of Pseudomonas 0-3 which Utilizes Polyvinyl Alcohol

A soil-isolated bacterium has the unique ability to use PVOH as its sole carbon source. It produces an enzyme that facilitates this process, showcasing applications in eco-friendly waste treatment.

- Water Soluble Polymer Biodegradation Evaluation Using Standard and Experimental Methods

Various types of polymers, including polyethylene glycol (PEG), polyvinyl alcohol (PVOH), and carboxy methyl cellulose (CMC), were tested for biodegradability in standard screening tests. PEGs and PVOHs showed high levels of biodegradation.

- Multi-Laboratory Evaluation of the Reproducibility of Polymer Biodegradation Assessments

This study examined how different test methods and variables like polymer type, test duration, and concentration affect biodegradation. Results showed that there was low variability within and consistent biodegradation results, suggesting good reproducibility.

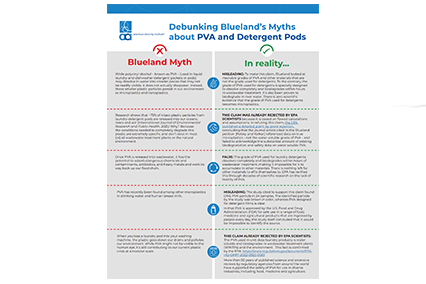

Blueland Claims

Because this chemistry has enabled these innovative laundry and automatic dishwashing product formats, it is extremely disappointing to learn about the misinformation that is being spread about PVA/PVOH. An ongoing marketing campaign has been funded by Blueland with an interest in preventing other companies from using this technology. This aims to discredit PVOH and the companies that use it and ignores decades of science and research demonstrating the biodegradability of this chemistry. Efforts include an EPA petition and legislation to ban the use of the ingredient in detergent pods and sheets.

The EPA denied a petition filed under the Toxic Substances Control Act (TSCA) requesting health and environmental safety testing for polyvinyl alcohol used in detergent packets, noting that it lacks factual evidence. Additionally, the request to update PVOH's status on the Safer Chemical Ingredients List (SCIL) has been denied, as there is a clear weight of evidence showing that it meets the Safer Choice Standard.

A proposed bill in New York City would restrict the use of polyvinyl alcohol, (also known as PVA or PVOH), a water-soluble polymer used to make sustainable laundry and automatic dishwasher detergent packets. We take a look at the science to separate myth from fact.

Key News

Releases

- Time to Unravel "Deliberate Deception" on Banning Detergent Pods (02/26/2024)

- EPA Maintains Safer Choice Status of Essential Chemistry Used to Make Detergents (04/25/2023)

- Misinformation Campaign on Valuable Chemistry Used in Detergent Products (11/15/2022)

- Attack on Detergent Packets Ignores Decades of Evidence on Film Biodegradability (07/27/2021)

Articles

- PVA or PVOH Ban Is Unnecessary and Impedes Sustainable Fabric Care Innovation (HAPPI - 02/08/2024)

- Polyvinyl alcohol film still OK in cleaning pods, EPA says (Plastics News - 05/05/2023)

- Are detergent pods really biodegradable? (The Washington Post - 11/15/2022)

Learn More

- Do Laundry Pods (PVA) Create Microplastics? A Dry Cleaners Research Based Deep Dive! (Jeeves NY)

- Explainer Video on Disappearing Polymer Technology (Monosol)

- What is PVA & Why is it in Your Laundry Pods? (Home Made Simple)

- What is PVA (Polyvinyl Alcohol)? Is it Eco-Friendly? (Green Eco Dream)

- How Does a Laundry Detergent Pods Packaging Machine Produce Pods? (Polyva)